Working principle and structure

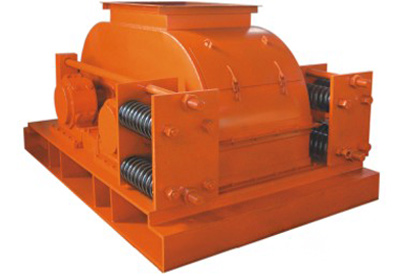

1, the series of roller crusher is composed of roller, roller bearing, compression and regulating device and drive device and other components.

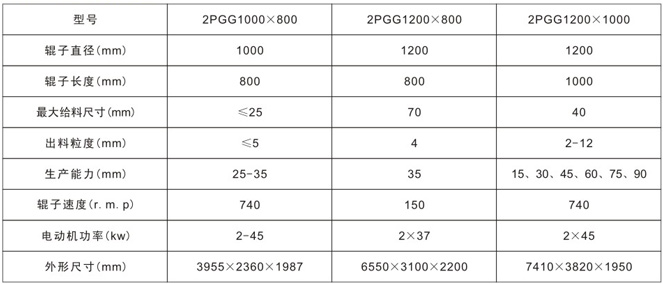

2, the adjustment of the material size: between the two rollers with wedge or gasket adjustment device, the top of the wedge-shaped device with adjustment bolt, when the adjustment bolt up the wedge up, the wedge will move the top roller away from the Fixed wheel, that is, the gap between the two rollers become larger, the material size becomes larger, when the wedge down, the activities of roller in the role of compression spring wheel gap smaller, smaller grain size. By increasing or decreasing the number or thickness of the gasket to adjust the size of the material size, when the increase in gasket when the gap between the two rollers become larger, when reducing the gap between the two roller pads become smaller, smaller grain size.

3, the drive mechanism is composed of two motors, driven by the V-belt to the sheave wheel drag on the wheel, in accordance with the relative direction of movement rotation in the crushing of materials, the material from the feed port through the roller, crushed by crushing, broken The finished product is discharged from under the chassis.

4, for safety, the transmission part of the actual situation should be installed according to their own security shield.

Please fill out reservation information, will respond to you as soon as we receive! You can also contact us directly call 0421-7265358